I dont know why they have to lie about it. At $5/8ft board you’d think I paid for the full 1.5. Edit: I mixed up nominal with actual.

Shouldn’t the normal size be 2? Given, well, the name?

You’d think so, but no.

Short story is the ‘nominal’ size is the size before going into a planer to smooth the faces.

Yes, it makes little sense, like many things related to construction stuff.Yeah sorry. The tree was originally 50ft tall so we call the pieces that. But you only get 3ft

Is like buying 1200lbs steaks because that’s what the cow weighs before it gets parted

Better example would be raw vs cooked weight of a 1/4lb paddy.

That’s a very small area to grow rice in.

Or a very offended Irish person.

It’s not a 2x4 it’s a “2x4.”

nominal

The convention is 2" before milling. Milling takes off 1/4"on each side, so the result is 1.5".

Is this a joke? (I know it isn’t).

Why would I want to know the dimensions of the unfinished product? I’m not a construction worker, so honestly is there any reason?

Lumber is weird because it has been industry standard to lie about dimensions since before the US existed so it’s just kinda a thing they get to do

No its not Maybe in the US? At least here, it is and has to be, very precise especially when it comes to industry quality. It is precise down to the mm!

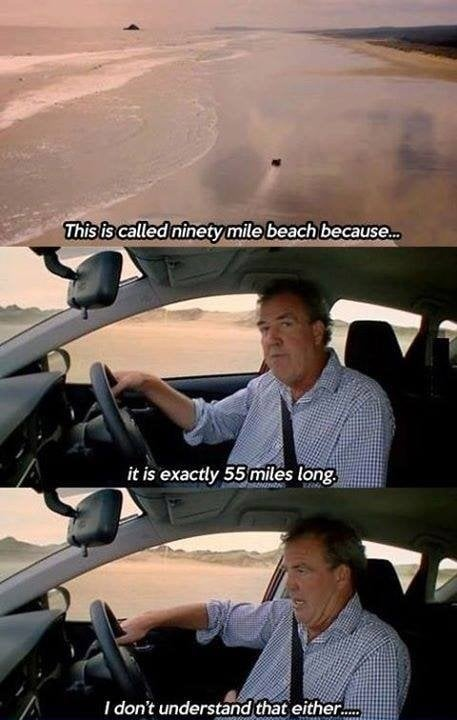

Yeah but they measure in feet and cheesburgers.

And lies, don’t forget the lies

In bullshit, which is itself an imprecise metric.

Alternative facts, thank you very much

It’s not exactly a lie, just a standard. Nominal board sizes were based on the unfinished lumber size. Another 1/4 inch is taken off each side to get a smooth surface that makes it easier to work with.

Here’s an old image (reddit warning)

that shows the rough cuts of boards from a log. When they look at a log, they determine how many of each size they can get from it, and at that point, a 2x4 is 2 inches by 4 inches.

Why does the consumer need to know the dimensions at harvest when it’s been processed multiple times?

That’s like calling an 4oz can of evaporated milk a gallon because it came from a gallon of milk before processing (I have no clue on the ratio)

I agree with this. Use whatever system you need or want internally, but there’s no reason to force whatever archaic or industry system onto a consumer. Logcutters also use a 1"=1/4 system and that is how they sell wood. A piece of wood that is 2" thick is sold as 8/4. Not 2". I get that they have their system but it seems dickish to force the consumer to use that system. There could be a good argument for it, but I’ve not heard one beyond “what, can’t you do math?”

It’s like a 1/4lb paddy being a different weight before and after cooking. They can’t tell you the final weight, since it’s always going to be different. Same with wood.

The woods final actual dimensions can vary, so they tell you its original size.

A 2x10 can be anywhere from 9-3/8thick down do 8-3/4 depending on how it dries.

I get that. But this is for kiln dried wood. And this particular issue I’m removeding about isn’t about net loss. It’s selling wood using an internally useful measuring system instead of how the consumer would actually think about it. It’s adding needless complexity, in my mind, when there’s enough factors to consider.

The consumer (people who work with lumber) knows how the system works. You don’t, because you don’t work with lumber.

If the boards were precisely measured in mm and binned accordingly, it would help no one because all construction techniques developed for use with lumber account for dimensional inaccuracy.

Building and working with lumber is different than working with manufactured materials like plywood or whatever.

The two-by-fours at your local home center are not 2 inches thick or 4 inches wide…not anymore at least. They spent several weeks at that size though. The sawmill cut them to that size to stack and kiln dry, and then when removed from the kiln they are then milled straight and square. Used to be they would sell the rough stock to carpenters who would do the milling themselves, but then they figured out that the railroads were charging them a fortune to ship a lot of wood that was going to be ground to sawdust anyway, so they started milling the boards before shipment. Same amount of construction lumber arrives at the construction site and it took less fuel for the locomotive to deliver it.

they are then milled straight and square

Lol. Trying to find lumber that’s straight and square is a pipe dream these days.

It was straight and square when it was milled. Problem is that the big box stores cut corners during the kiln drying phase, so the boards have a ton of moisture still in them. As that dries, the boards twist and cup.

Plus poor protection from the elements at each storage step, which means rapid temp changes, which also causes wood movement.

Go to a local lumber yard. They tend to do a better job at kiln drying. You’re still going to have warped boards, but far fewer in my experience.

As if american measurements have ever made sense. Look up how they measure screws or wires and despair.

It’s a wonder they manage to build anything. They have pocket calculators dedicated to the building industry. It’s surreal.

Not everyone

Some people are gods when it comes to metal math

🤘🏻

every house I’ve lived in has had something fucked up in it. Even if you have one guy doing everything correct, you have 20 other contractors coming in that can’t do basic addition and subtraction, let alone fractions.

My parents just had a house built last year and there is so much shit wrong. The biggest thing I found is one of the alcoves on the side of their fireplace is a full 1.5" wider in the front than the back. You don’t have to measure to see it. How the fuck the guy who did the framing, or the guy who did the drywall, or anyone else walking past that fucking thing didn’t notice I have no idea. They sold their nice old house for that pile of shit and it’s not even better even if you ignore all the problems. It pisses me off so much because I told them this was going to happen.

They were when the name was made, but due to changes in the manufacturing process, they aren’t anymore. The name stuck, though.

https://www.popsci.com/two-by-four-lumber-measurements-explained/

So don’t fret. The next bundle of 2-by-4s you pick up in the hardware store are certain to be the exact same size: 1.5-by-3.5 inches.

So they can measure precisely, after all

Ans yet this piece is 1.28

1.28 is the new

21.5

Is nobody gonna call out OP for wearing socks with sandals? …and, ostensibly, while preparing to do carpentry?!?

That’s like a cardinal sin squared!

Jesus did it

Not in socks

No need to crucify him for it.

I regularly wear socks and sandals along with shorts and a sweater.

There was also a time I went to lunch with that plus a lab coat and hairnet.

Sounds like a Rick and Morty episode.

Can’t you see those are safety sandals. And just like safety squints, are approved PPE across the whole 3rd world industrial sphere. OP will be perfectly safe.

Nope. Definitely dead.

don’t forget the unbranded Chinesium calipers.

Mitutoyo or bust.

For a machinist yep. For home gamers, a waste of money. They don’t have the knowledge of where and when to use them nor the skills to get accurate repeatable measurements. So for OP’s use whatever CCC, (Cheap, Cheerful, Chinese), caliper he’s got is good enough.

It’s the definition of “nominal size is what ever we say it is” that pisses me off. Buying wood/lumber is the worst offender of Nominal sizing, but even metals are getting worse. I used to buy a round bar of say, ASA1018 and it would be +0"/-.002". It’s now +0/-.006", (that’s +0/-.05mm and +0/-.15mm for those living in Boca Raton). At the end of my career as a toolmaker I was often forced to purchase oversized stock and waste time turning said stock into the actual sizes required.

My toolbag calipers are cheap hardware store ones. They’re accurate enough and I’m not out much when they inevitably get damaged or lost.

Nah nothing wrong with wearing socks with sandals when you’re home. Do what ever the hell you want.

But I do agree with wearing proper footwear while doing dangerous things.

Oh absolutely. I wear socks with sandals because my soles sweat and make my sandals sticky.

But yeah, wear proper attire for the work you do!

Steel toe capped crocks

I love this idea. I’m not even sure why, I don’t own crocks.

Um, wait. I would think that violates some sort of law (but I guess maybe we haven’t codified this?). I mean, building plans expect standards in materials, right? So how can a building meet codes if the materials are not within the expected specs?

Agreed, seems like some kind of weights and measures violation.

I’m going to guess they can get away with this because 2x2s aren’t intended for structural use. I’ve never built one into a floor, wall or ceiling.

Used for furring strips everywhere. Line a block wall with them and sheet it for example.

To someone from central europe it’s always weird how houses get build from wood in the US. 😅 I imagine you can hear ~everything happening ~anywhere in the house?

it’s extremely common for americans to dismiss apartments because they simply cannot fathom the idea of housing that actually blocks noise, it’s one of the primary arguments i see used against denser housing.

Would you call that a “structural use?”

Structural use means load bearing. So no.

Furring strips are used in plenty of places, I provide one example where it is used in most residential homes to support drywall.

Is it not structural if it’s holding ceiling drywall…? So why are people still bickering that walls aren’t structural when they still hold drywall up…?

If it’s part of a code wall detail, would that not be structural…?

What’s with the pedantism over something like this to try and save face over not knowing what a furring strip is?

Furring strips and drywall don’t count as load bearing. Structural means that it carries the weight of the overlying structure. Basically if the building falls down if that element is missing, it’s structural. So staircases for instance are almost never structural. Many interior walls are not load bearing so they can get knocked down without consequence. You can also split a room by building a wall that won’t be load bearing.

Furring strips and drywall don’t count as load bearing.

Except for the thousands of use cases where they are used for lateral bracing to support the structure….

Like in shear walls… strapped drywall ceilings… load bearing walls….

Yes they can be used non-structurally, I’ve never claimed otherwise, yet you are ignoring the fact that they can, and are used in load bearing structural applications……

No, that’s is not structural.

Structural means it’s intended to support and transfer loads in a way that cannot be safely removed.

Since neither the furring strips or drywall are part of a structural requirement, they are not load bearing.

Drywall is structural, when used on block walls it helps provide lateral support.

This is why being pedantic usually backfires.

Drywall is inherently structural.

Regardless. It’s furring strips, you want to argue furring strips aren’t used in structural applications? They are used in all three applications the person said they haven’t used them in. They also claimed to be a wood wroker elsewhere, so I don’t see how they would use anything structural anyways….

That was one example, you can also strap roofs to install sheet metal cladding. Is that not structural? Strap a ceiling? There’s a ceiling use for you.

I figured if I gave you a real world example you could do a little research of your own. Even googling 2x2 will get you a big box store furring strip page. You should know what furring strips are if you are in the industry.

No, that’s not structural since the furring strips are not integral to load bearing capacity of the structure.

In your sheet metal example, they are only there for visual reasons - to help keep the roof flat. The roof can be put down without the furring strips. It might bend, but it still function as a roof.

The roof can be put down without the furring strips. It might bend, but it still function as a roof.

What…? Roof trusses go parallel with the length of the cladding panel, you require furring strips on the perpendicular to install them. Just like in a wall with the studs vertical, you need horizontal furring to install them.

These required larger furring strips due to truss spacing.

Furring strips are not visual lmfao. They are structural components in a lot of assemblies. Without knowing the assembly you can’t say if they are or aren’t structural, that’s the entire point I’ve been trying to make here. You aren’t the quickest one are you? I’ve pointed this out multiple times. There are thousands of use cases where furring strips are structural. To say they aren’t structural is fucking asinine lmfao.

Those aren’t furring strips in that photo. That’s dimensional lumber. In this case, those spans are large enough that they require the strength of actual lumber.

The 2x4s that have been sized this way do meet structural code. It was found that a full 2x4 is way over spec’d for what they were used for, so why bother wasting extra parts of the tree?

Pretty much everything built with dimensional lumber in the last century has been done with undersized 2x4s, and it’s fine. The name stuck for historical reasons. Companies that build houses and order this stuff by the pallet all know what the real size is, and so do building inspectors.

Pretty much everything built with dimensional lumber in the last century has been done with undersized 2x4s, and it’s fine.

It’s fine, folks. Nothing to see here.

It’s probably 2x2PT or something. There are standards for board widths.

Well shit. That explains alot

I appreciate you covering your open toes, safety socks so you’re compliant.

This was pre-job time :) Testing a 3d printed joint with it when I noticed the wood was very undersized.

2x2PT has been 1.25x1.25 for as long as I can remember (10 years or more). It’s only the pressure treated deck stuff for railings. This does not apply to the rest of the 2x lumber, as those are still 1.5 actual. I got Simpson corner 2x2 brackets for crazy cheap way back but ended up not really using them. The 2x2s are warped to hell and a ripped 2x4 was too big in the original 2x dimension.

I’m wondering if it’s a regional thing? I just looked online for pressure treated 2x2’s and all the ones I’m seeing (home hardware, home depot, advantage lumber, etc) list as actual being 1.5x1.5

That’s possible. I just moved from CA to MI 2 years ago. I know they were 1.5 then because I built alot of props and temp walls with it. I was reusing a 3d printed joint I designed to make a garden trellis when I noticed the wood didnt fit like before.

Is their entire stock like this every time, or just this one batch?

Entire stock as of 5/6/24. I didnt even notice it was smaller than usual, busy trying to find the only-slightly warped boards.

It’s still a bit small, but pressure treated being a little smaller than framing lumber is not necessarily a secret:

Beat me to it!

RIP Jack Nance and Ed Wright.

Top comment, this. This is gonna be my default when folks ask about dimensional lumber sizes in the future

Nothing is immune to shrinkflation aka merchant gouging

What is your definition of gouging

Highly relevant when topically adjacent to woodworking.

Why is 2x2 meant to be 1.5x1.5 and not 2x2?

*Planed/straight wood versus raw lumber. It threw me off when I first started building stuff and summed that a 2x4 was actually 2"x4" in all my measurements/plans

*Or it would be straight if you’re lucky and don’t pick from the top of the bin at Home Depot

Distributors send their junk to home stores because they know they won’t reject it.

They don’t even send back the garbage pieces, just restock if they get returned

TBH that looks like a furring strip, not dimensional lumber

It’s possible they stocked the wrong thing, but it was rung up as Pressure-Treated so maybe they applied the wrong barcode?

That green tint means it is pressure treated. Just take it back (this time bring a tape measure.)

And clip it to the belt loop of your khaki cargo shorts like the rest of us weekend warrior dads 😂

I usually bring my 9ft magnetic tape from my car’s ceiling and my 4" brass fractional caliper from the glove box into the store but always end up prowling the lumber section for the loose tape measures. Wouldn’t want to look like I’m stealing, right?